Die Casting in Malaysia: Precision Engineering for Trendy Industries

Die Casting in Malaysia: Precision Engineering for Trendy Industries

Blog Article

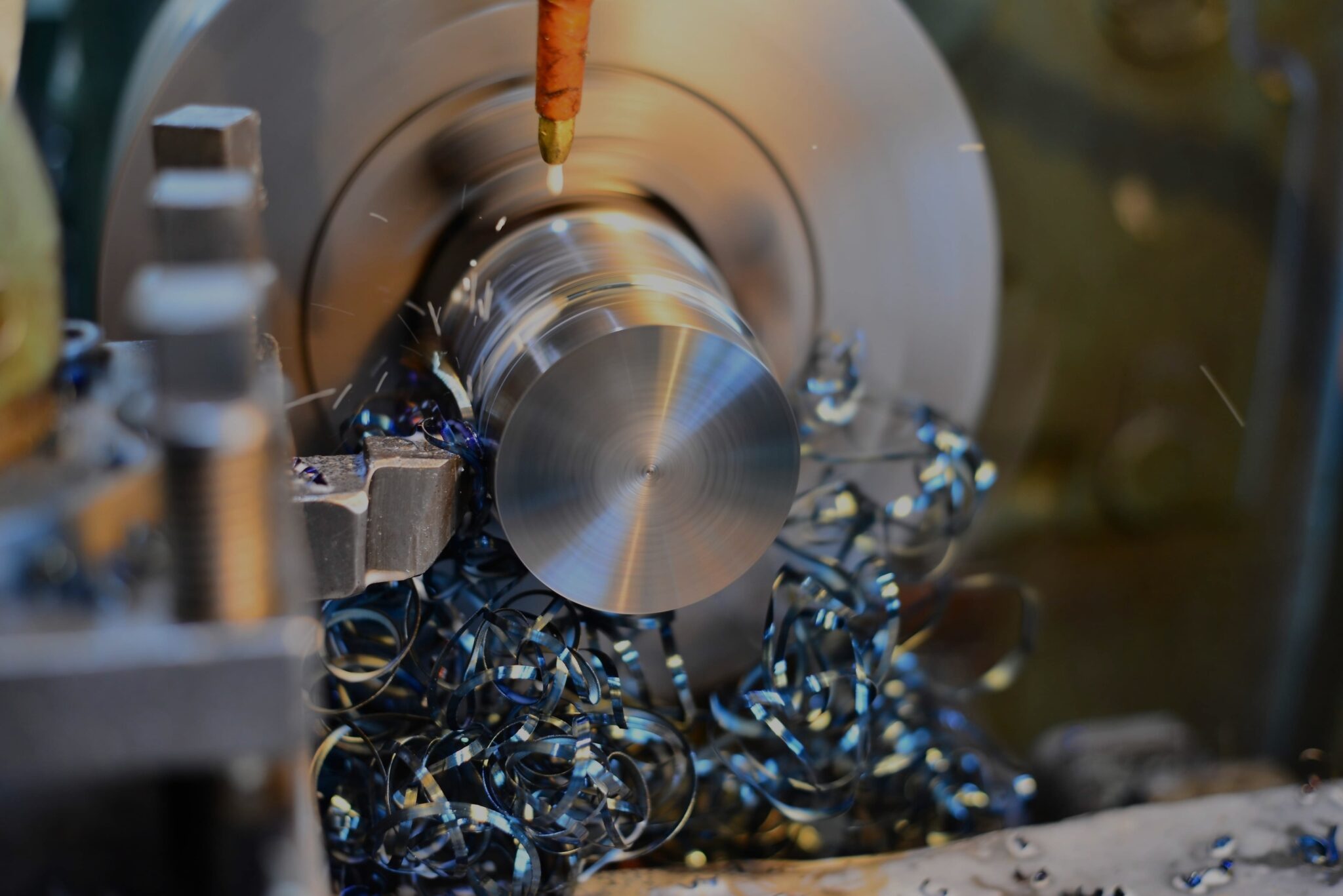

Die casting Malaysia has emerged as an important sector of manufacturing in the country that supports various sectors like electronics, automotive, aerospace, and consumer goods. The process involves injecting hot metal into molds under high pressure, creating complicated and precise components that have no post-processing needs. In the face of increasing need for high-strength, lightweight sturdy metal products Die casting has evolved into an essential manufacturing technique in Malaysia. This industry has benefitted from Malaysia's well-established industrial infrastructure, skilled workforce as well as government assistance for promoting manufacturing technology that is high-tech. As Malaysia grows as a manufacturing hub in the region and a die casting industry is a major factor in promoting innovation and economic development. Businesses in the industry invest in cutting-edge techniques to increase efficiency, precision, and sustainability.

The automotive industry is one of the largest users of die-cast parts in Malaysia because manufacturers depend on this method to create durable and lightweight vehicle parts. Engine blocks, transmission case, and structural components are often made from aluminum and magnesium alloys due to their high strength-to-weight ratio, as well as their the resistance to corrosion. As the trend shifts to electric vehicles , the need for precise die-cast parts is growing as companies focus on enhancing efficiency and decreasing the overall weight of vehicles. There are many Malaysian die-casting firms have formed alliances with international automotive companies providing essential components that are in compliance with international standards for quality. The country's role in the automobile industry is strengthened by the investment in research and development, which help improve production techniques and help ensure that companies remain on top of the game in an ever-changing market. As automation is integrated into and smart manufacturing, the die-casting sector is expected to grow more efficient and innovative in the coming years.

In addition to the auto industry, die casting plays an important role in Malaysia's electronics sector, which is one of the largest export sectors in Malaysia. The precision and consistency of die-cast parts are ideal for the production of electronic casings, heat-sinks and connectors. As consumer electronics and telecommunications gadgets become smaller and more efficient, the demand for precision die-cast parts will continue to increase. Malaysian manufacturers are adopting new technologies such as vacuum die casting and semi-solid casting of metal to improve product quality and reduce defects. With a robust supply chain and accessibility to international marketplaces, Malaysian die-casting companies have established themselves as reliable supply chain partners for multinational electronics brands. As 5G technology and smart phones become widespread, the demand for precision-engineered die-cast parts will likely to grow.

Sustainability is now a major issue for the Malaysian die-casting industry, with companies actively implementing sustainable manufacturing methods. Reuse and recycling of metal materials, particularly zinc and aluminum, are becoming commonplace practices in die casting, reducing waste and conserving resources. Many manufacturers have also adopted the most energy efficient melting and casting techniques to reduce carbon emissions as well as overall energy consumption. A shift towards sustainable manufacturing has prompted the industry to explore more environmentally friendly casting methods, including low-pressure die casting and gravity die casting. These techniques create high-quality products with less waste. Coatings and surface treatments that enhance the durability and corrosion resistance of die-cast components are also being developed with eco-friendly materials. With industries around the world pushing to create more sustainable supply chains, Malaysian die-casting businesses are positioning themselves as the leaders in the field of sustainable metal casting making sure they are competitive in the long run on the global market. To find more details kindly head to Senadiecasting

The continuous advancement in the design of molds and tools has greatly enhanced the efficiency and quality of die-casting Malaysia. High-quality molds are essential for making components that are free of defects, and companies have embraced computer-aided design and computer-aided manufacturing software to enhance the accuracy in their moulds. Simulation software allows engineers to anticipate potential flaws and to optimize the casting parameters prior to production cutting down on material waste, and increasing the consistency of product. The integration of robotics and automation in the molding process has also streamlined the manufacturing, which allows companies to manufacture large quantities of components with minimal human intervention. The technological advancements have not only increased productivity but have also cut costs, making Malaysian die-casting companies more competitive on the global market. As industries demand higher quality and effectiveness, constant investments in mold design and the tooling process will be vital to sustaining the growth of the sector.

Looking to the future, Malaysia's die-casting industry is predicted to see substantial growth, driven by the latest innovations, sustainable practices as well as a growing need for precise metal components. Industry leaders and the government are working together to enhance the research and development of initiatives that encourage the implementation of advanced materials and new casting methods. The workforce training program is designed to equip workers with the necessary skills in operating modern die-casting equipment and automated systems. Since industries like electric vehicles, renewable energy and intelligent technology continue to grow, Malaysia's die-casting sector is well-positioned to meet the ever-growing demand of high-performance metal components. The country's strong industrial infrastructure and its dedication to innovation and sustainability will ensure that Malaysia is a major actor in the world die-casting marketplace. By implementing continuous improvement and strategic investment, the industry continues to propel the economy while maintaining its reputation for quality manufacturing.